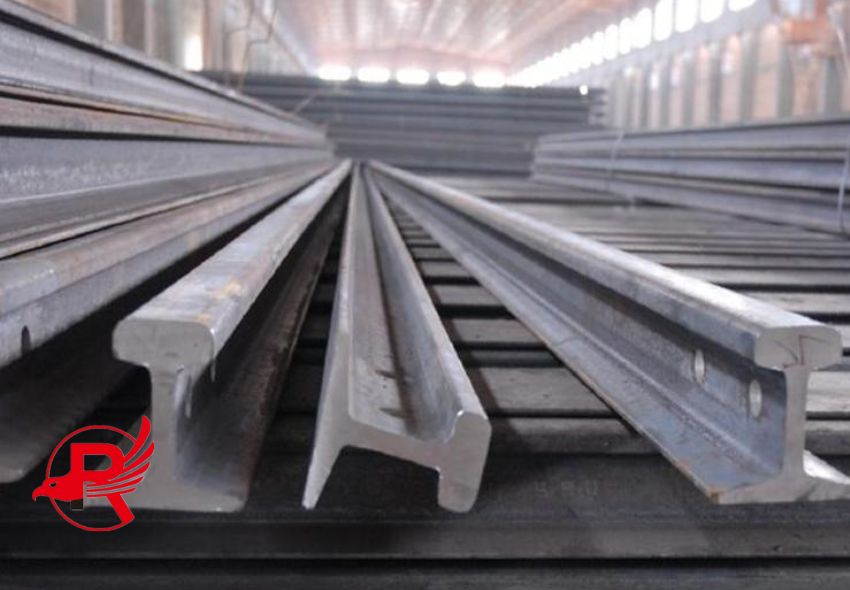

Производственият процес наGB Стандартна стоманена релсаобикновено включва следните стъпки:

Подготовка на суровини: Подгответе суровини за стомана, обикновено висококачествена въглеродна конструкционна стомана или нисколегирана стомана.

Топене и леене: Суровините се стопяват, след което разтопената стомана се отлива в предварителни стоманени заготовки чрез непрекъснато леене или изливане.

Рафиниране и валцуване: Рафиниране на предварителната стоманена заготовка, включително отстраняване на примеси и регулиране на състава, и след това валцуване на стоманената заготовка чрез валцово оборудване до релсови заготовки, които отговарят на националните стандарти.

Предварителна обработка: Предварителна обработка на заготовки за коловози, включително коване, термична обработка и повърхностна обработка и др., за подобряване на здравината и издръжливостта на релсите.

Валцуване и формоване: Предварително обработената релсова заготовка се валцува и формова чрез валцова машина, за да се получи релсов профил, който отговаря на изискванията на националния стандарт.

Инспекция и контрол на качеството: На произведените релси се извършва строга инспекция и контрол на качеството, за да се гарантира, че те отговарят на националните стандарти и изискванията на клиентите.

Опаковане и напускане на фабриката: Квалифицираните релси се опаковат и маркират, след което се доставят на клиента или се съхраняват в склада в очакване на доставка.

Адрес

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, Китай

Имейл

Телефон

+86 13652091506

Време на публикуване: 19 април 2024 г.